ENFIT Cleaning standards for food and feed transport units

International cleaning standards for the professional hygienic cleaning of transport units

When cleaning transport containers in which food or feed has been transported, it is usually important that these are cleaned particularly carefully and hygienically. This is especially true when cleaning food transport containers. Professional cleaning consists of several work steps, some of which require a lot of manual work.

A transport container consists not only of the container chamber or several container chambers, but of many attachments and accessories. These include: aeration and ventilation lines, manhole covers, seals, hoses, hose boxes, floor drain valves, filters, fittings for over and under pressure protection, pipelines, pumps, microfilters, pipe distributors or air distributors, baffles, protective boxes and much more. When it comes to cleaning all of these individual parts, good staff training and regular training are of primary importance. The details can be found in the ENFIT Guideline - Transport of unpackaged raw materials and food in food transport containers.

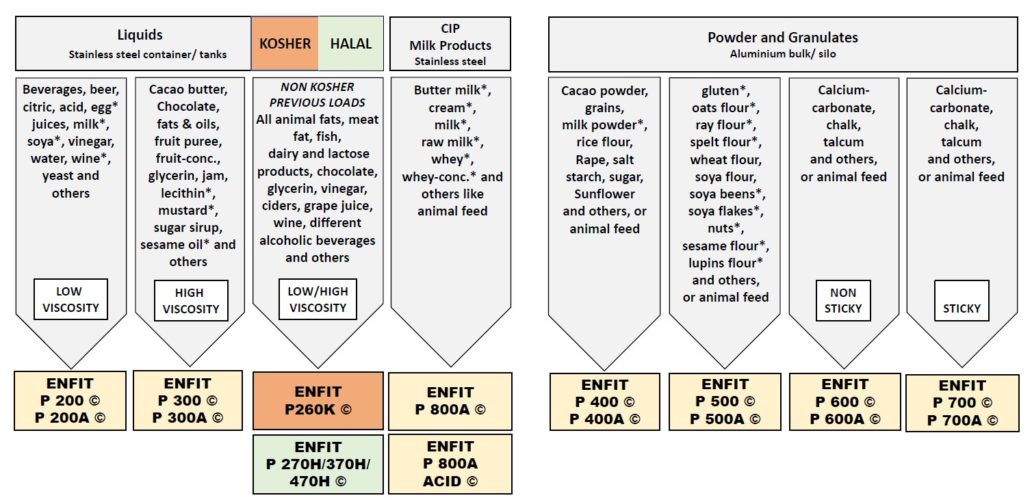

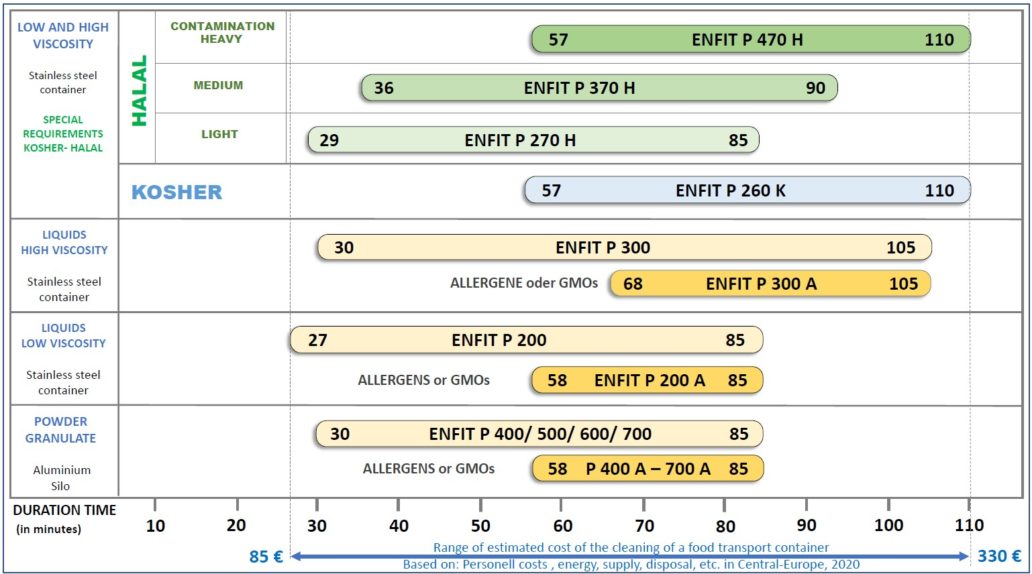

The ENFIT cleaning programs for the cleaning of food and feed transport containers were developed by the experts of the ENFIT working group. The cleaning programs depend on the different aggregate states (liquid, powder or granules) and the specific substance properties (viscosity, fat or protein content) and whether it is an allergen or a GMO (genetically modified organism).

When developing the cleaning process/cleaning programs, it was taken into account whether it was high-pressure cleaning without recirculation or CIP cleaning with recirculation.

The special requirements of cleaning according to KOSHER or HALAL requirements were also taken into account when developing the cleaning processes/cleaning programs. See chapter Kosher/ Halal. A total of sixteen different cleaning programs were developed and tested in practice.